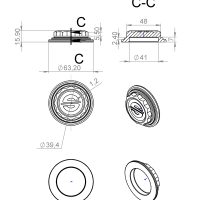

A customer approached us with a request to make three copies of a plastic bolt that was necessary for his work. The process began with a 3D scan of the original bolt using our high-precision 3D scanner. To achieve the best results, a special matte powder was applied to the sample, creating a white coating that improves the quality of the scan, allowing for more detailed capture of all the details and features of the bolt surface.

Once the 3D model was received from the scanner, our specialist began to refine it, eliminating possible inaccuracies and improving details to ensure the high quality of the final product. Having completed the model processing, we began 3D printing it on one of our 3D printers using FDM technology. For printing, we chose PET-G material, which is characterized by its strength, reliability and resistance to external influences, which makes it ideal for creating durable plastic products.

We offer a full range of services for 3D scanning and 3D printing of various components, such as bolts, gears, housings and other parts of mechanisms. Regardless of the complexity of the task, we use the best technologies and materials to ensure the highest quality and accuracy of each part manufactured on our equipment.

Controls

×- Rotate with the left mouse button.

- Zoom with the scroll button.

- Adjust camera position with the right mouse button.

- Double-click to enter the fullscreen mode.

- On mobile devices swipe to rotate.

- On mobile devices pinch two fingers together or apart to adjust zoom.

- On mobile devices 3 finger horizontal swipe performs panning.

- On mobile devices 3 finger horizontal swipe performs panning.

Industrial 3D Printing ChatGPT сказал: 3D printing for serious industrial projects requires extensive design experience and a deep understanding of manufacturing processes.Key …

3D prototyping It is a very important stage in the manufacturing process.Before starting mass production, it is necessary to carry out tests, …

3D prototyping It is a very important stage in the manufacturing process.Before starting mass production, it is necessary to carry out tests, …