3D prototyping

It is a very important stage in the manufacturing process.

Before starting mass production, it is necessary to carry out tests, strength assessments, visual appearance evaluation, and other usability factors.

3D printing a prototype makes it possible to create a mock-up (draft) of the part and conduct all the necessary studies.

Types of 3D prototypes

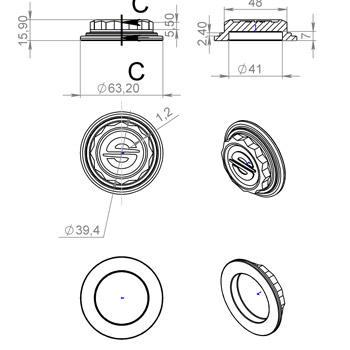

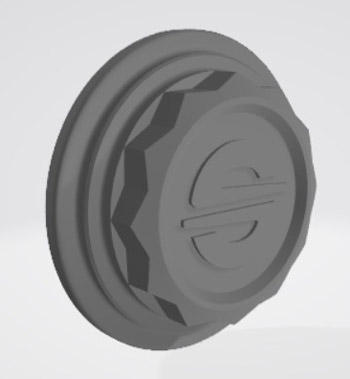

Visual prototype

It is used to evaluate the shape, dimensions, and external appearance of the part, without taking its functionality into account.

Functional prototype

This type of prototype makes it possible to observe the functionality of the future part, as well as verify the operation of the mechanics and the assembly.

Assembly prototype

It is intended to verify the correct assembly of the product from its various components.

Technical validation prototype

It is intended to evaluate the technical and physical characteristics of the part, check its strength, heat resistance, and how it behaves under real conditions.

FAQ

Yes, we have a team of 3D designers and engineers who can help you develop your idea from scratch, based on drawings, technical specifications, and descriptions.

On average, in the case of rapid prototyping, the manufacturing time is 2 to 3 business days.

Yes, all our services include a confidentiality agreement. For projects requiring greater protection, we offer the option to sign specific non-disclosure agreements (NDAs).