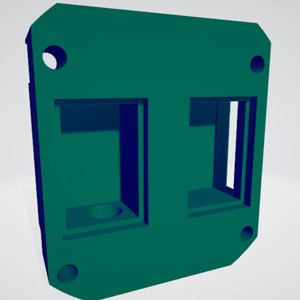

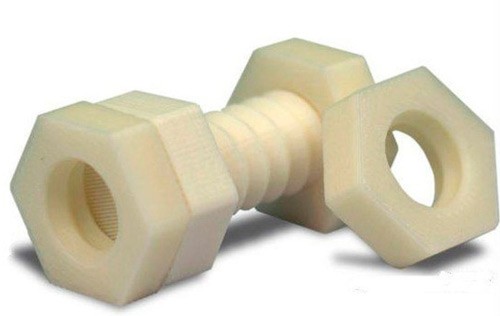

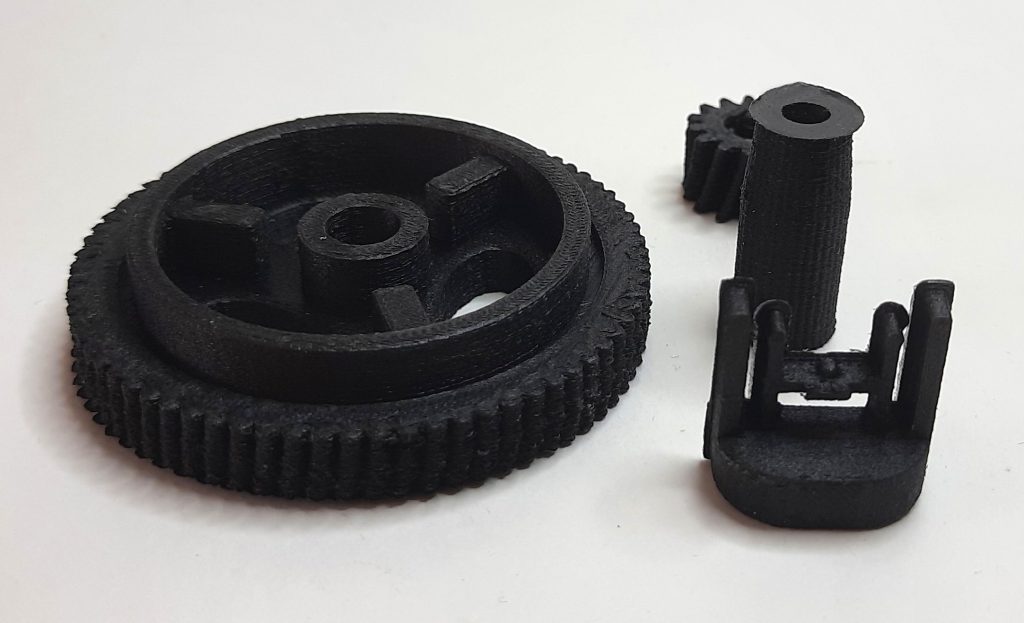

Many companies often need to manufacture parts in small or limited series. Typically, these are device housings, machinery, mechanism and machine parts, gears.

The requirements to the material, which are made quite often: impact resistance, bending strength, operating temperature range, resistance to external environment, transparency.

The most frequently used materials are ABS, PET-G, and when high strength is required – Carbon.

Professional manufacturing of 3d parts by 3d printing is usually done in 2 ways, which depend on the number of copies required.

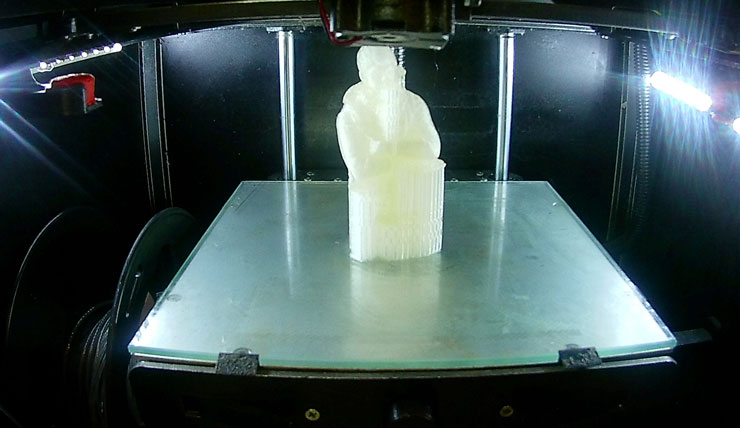

3D printing

If there is no need for mass production and the number of copies required is not too large (1-10 pieces), then from a price-quality point of view it is an ideal option. Why? Because the cost of casting is only more favourable when the number of copies is sufficiently large.

Moldeo

This is already a more complex and expensive production of parts.

The difference between casting and 3D printing is that it is first necessary to create a master model (a copy of the required part), from which a silicone mould is made, and then polyurethane is poured into the mould. This is a more complicated and time-consuming process than 3D printing, but the production cost is lower.

Our specialists are professionals in all methods and when you contact us they will suggest the best method for manufacturing 3D parts based on their experience.