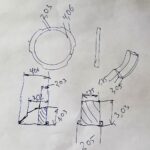

A client approached us to help create a 3D model of a lens holder based on their drawings, using a material of the appropriate type and quality. We carefully studied their sketches and technical requirements, then developed an accurate 3D model, taking all necessary dimensions into account. After selecting the optimal material, we printed the required number of holder copies on our 3D printer, ensuring high precision and quality. Once the printing process was completed, the products underwent quality control to meet the client’s requirements and were then shipped via a delivery service.

We specialize in creating 3D models and printing various components, including brackets, accessories, and fittings for eyeglasses. Our technologies allow us to manufacture parts with the highest precision, using the latest and most advanced materials suitable for a wide range of operating conditions. If you need to produce unique or serial parts, we are ready to assist you at every stage—from design to final production—on a turnkey basis.

Controls

×- Rotate with the left mouse button.

- Zoom with the scroll button.

- Adjust camera position with the right mouse button.

- Double-click to enter the fullscreen mode.

- On mobile devices swipe to rotate.

- On mobile devices pinch two fingers together or apart to adjust zoom.

- On mobile devices 3 finger horizontal swipe performs panning.

- On mobile devices 3 finger horizontal swipe performs panning.

Industrial 3D Printing ChatGPT сказал: 3D printing for serious industrial projects requires extensive design experience and a deep understanding of manufacturing processes.Key …

3D prototyping It is a very important stage in the manufacturing process.Before starting mass production, it is necessary to carry out tests, …

3D prototyping It is a very important stage in the manufacturing process.Before starting mass production, it is necessary to carry out tests, …